Let’s Compare

Across dozens of industries and in a countless number of applications, product designers and manufacturers have turned to thermoplastic elastomers (TPEs) and liquid silicone rubber (LSR) to replace natural rubber. As suppliers of these materials continue to develop innovations in chemistry and capabilities, the appeal of both TPEs and LSR will grow even stronger.

Choosing between TPEs and LSR can be tricky. You need to evaluate a wide array of material performance and processing factors in context of product specification and budget requirements. The ultimate goal is to achieve the results you want in the most cost-effective manner by using the material that is best suited to your application. This high-level, objective look at both TPEs and LSR touches on some key topics to consider in three critical categories—design, production and performance—to help you make a more informed decision.

Thermoplastic Elastomers (TPEs)

Thermoplastic Elastomers (TPEs) are a diverse family of rubber-like materials that can be repeatedly melt processed. No matter how many times you expose TPEs to sufficient heat they will become soft and re-harden when cool. This defines TPE as a thermoplastic polymer material.

Liquid Silicone Rubber (LSR)

Liquid Silicone Rubber (LSR) is a silicone based product that is supplied as a liquid that is cured with heat to form a permanent shape. This makes LSR a thermoset polymer material.

Design Matters

Haptics

How a product feels to the touch is often an important factor in design, particularly on surgical instruments that require a combination of grip and control, or on consumer goods that are frequently handled. TPEs offer flexibility through chemistry. Depending on the formulation, TPEs can produce a range of tangible finishes —from silky smooth, to slightly tacky, to very grippy. When using more sustainable TPEs — those formulated with recycled or bio-based content — the range of haptics may be more limited depending on the sustainable content source or possible inconsistencies in those raw materials. LSR will yield either a dry, slippery surface or a soft, rubbery feel not unlike that of human skin. It is also possible to add additional surface texture to a finished product by bead-blasting or chemically texturing the mold used in processing either material. Adding surface texture can make harder grade TPEs feel softer to the touch, so your product can benefit from both qualities. Do note that LSR is generally more capable of reflecting a nuanced mold texture than thermoplastic elastomers because silicone rubbers exhibit a low viscosity that allows it to flow more easily across the entire mold and into complex geometries.

Colors

Color can help differentiate your product from the competition on a retail shelf, dazzle your customers with a variety of unique choices, or even add an element of safety to your design. Both TPEs and LSR offer a full spectrum of color options. As a raw material, LSR is generally transparent. Colorants added in the mixing phase of the manufacturing process can generate transparent, translucent or opaque colors. With treatment, LSR can overcome its tendency to attract dust. So a surface treatment is recommended for products such as wearables. Like LSR, TPEs offer you the chance to achieve a wide variety of colors and special effects with relative ease. Liquid colorants will produce transparent, translucent and tinted color. Solid colorants are better for generating highly opaque colors—including metallic, pearlescent and glow-in-the-dark colors—or patterns and effects, like marbling, wood or camouflage. Starting with water-clear grades of TPE will generate the best pearlescent and metallic colors. When considering sustainable content TPEs, recycled content formulations have more limitations based on the comingled nature of recycled raw materials. On the other hand, bio-sourced tend to be more opaque, making them easily colorable, but they do have a different tint than prime raw materials.

Complex Geometry

Your product or part may call for a design that features both thick and thin walls, complex shapes or intricate details. LSR flows easily into molds with varied wall thicknesses and can fill very long, thin sections of a mold. Though the viscosity of TPEs are reduced when processed at high shear rates, TPEs must be “packed” into a mold to ensure complete fill-out. There is a broad spectrum of TPEs available that have higher flow lengths, however, there are some limitations at certain durometers — particularly with harder formulations that measure greater than 50 Shore A durometer. When designing TPE parts, strive to keep the part wall thicknesses as uniform as possible and radius all sharp corners.

Overmolding

Hand tools, smartphone cases and razor handles are examples of products that benefit from using a combination of soft and hard textures to improve grip, add tactile sensation or cushion impact. Both TPEs and LSR can be used to add a soft grip on top of a hard substrate.

Because LSR cures at high temperatures, using it as an overmold material in a two-component molding system requires pairing it with high temperature thermoplastics to overcome the risk of melting or deforming the substrate. If overmolding is not feasible with silicones, you can use surface conditioning, primer and adhesives to chemically bond LSR to substrates. When properly selected, overmolded TPEs will form a strong bond (a cohesive bond) with the thermoplastic substrate without the need for primers or adhesives. One caveat: Typical TPE shrinkage is around 2% while that of substrate materials is closer to 1%. Specifying a substrate thickness of at least double that of the overmolded layer of TPEs will prevent warpage caused by this difference. Another consideration is that recycling either material once it’s overmolded, whether cohesively or with adhesives, can be a challenge.

Production Considerations

Raw Material

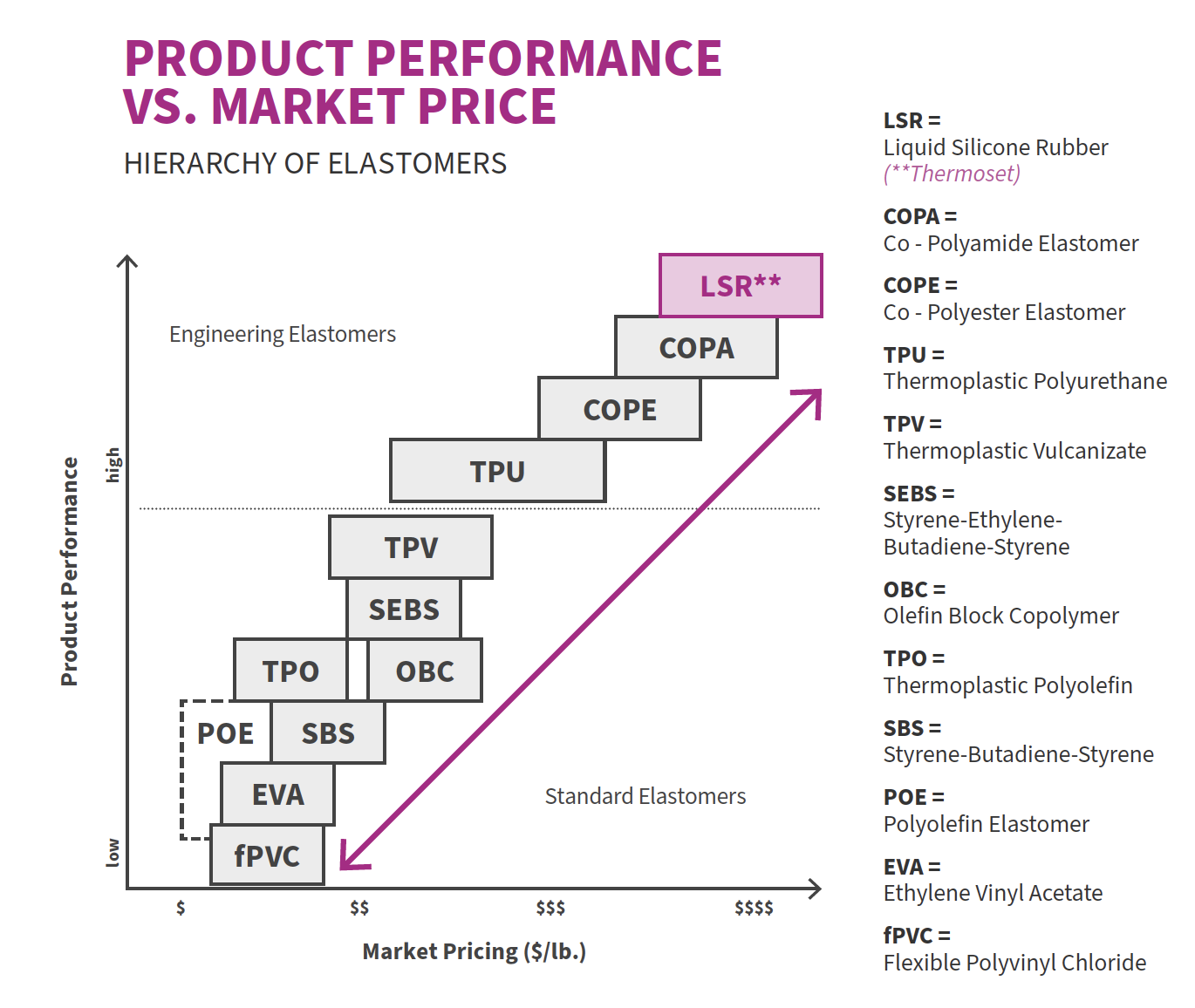

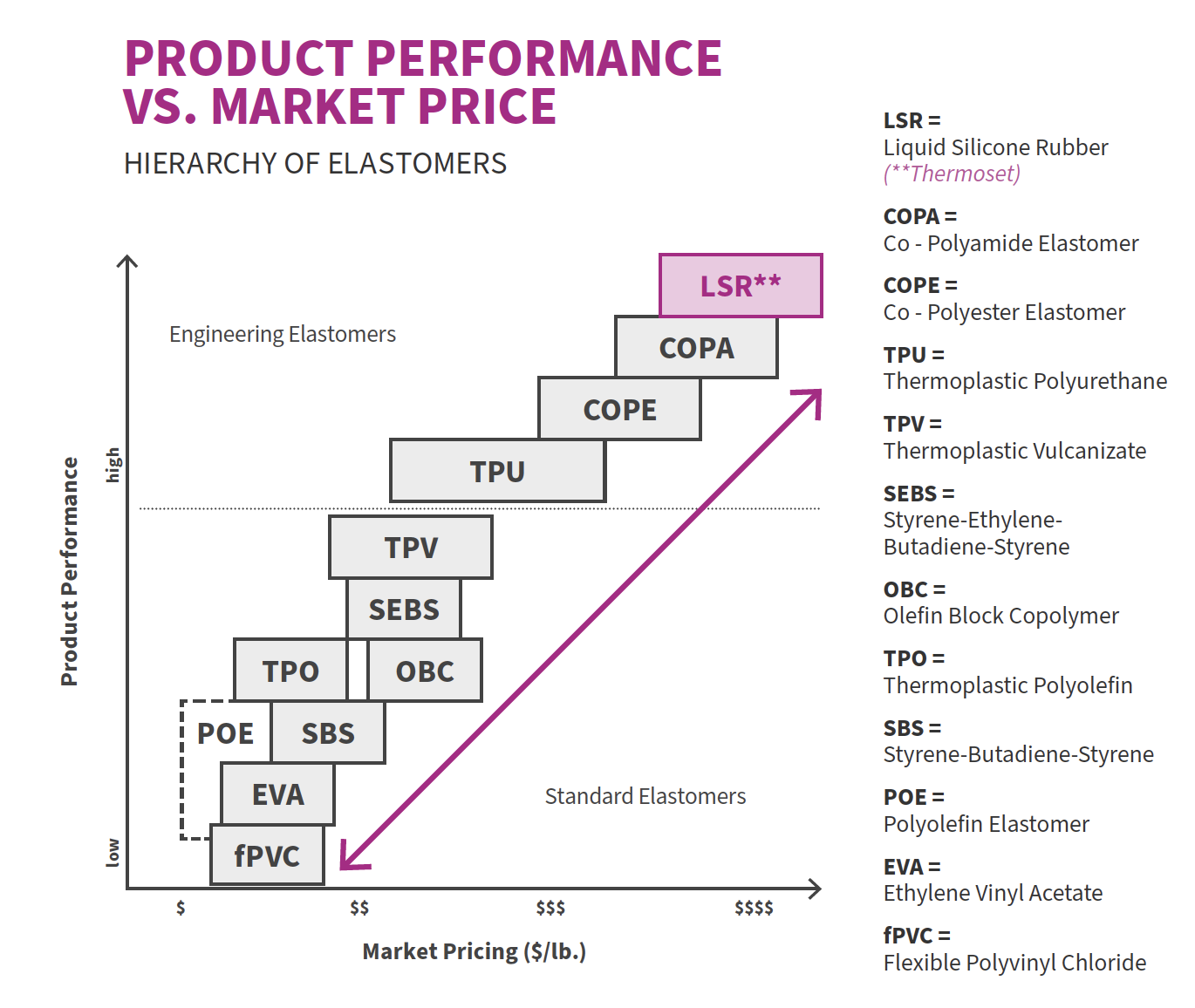

LSR and other engineering elastomers typically cost more per pound than standard elastomers. Additionally, LSR has a specific gravity that is 20% higher than TPEs (+/- 1.12 versus +/- 0.89), which means LSR will produce 20% fewer parts for every pound of material used.

However, when your application calls for a material that won't soften at higher continuous use temperatures, LSR is the answer. TPEs, however, have an advantage when it comes to recycling. Unlike LSR, they can be easily recycled and reprocessed, virtually eliminating waste from the manufacturing stream.

Comparing Prices and Determining Value

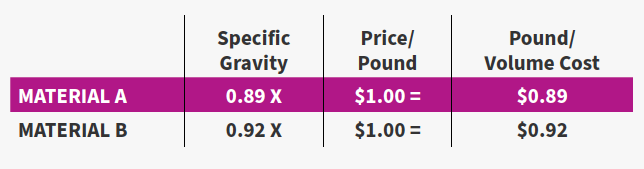

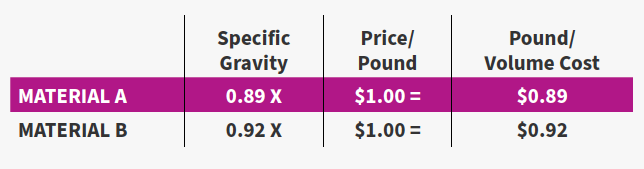

It seems logical to compare the price of different materials. However, price per pound is just one aspect of the overall cost. Materials with lower specific gravity will fill more volume and therefore yield more parts per pound. By factoring specific gravity along with price per pound, you can identify the cost for the amount of material you need to fill a given volume, as in your mold cavity.

Use this simple calculation: Specific Gravity X Price Per Pound = Pound/Volume Cost

Consider the example below. All other factors being equal, the volume cost of Material A makes it a better overall value, even though the upfront price per pound of the two options was the same.

Considering Sustainability

Based on the raw materials used and manufacturing practices, these materials have a different product carbon footprint (PCF). For example, the use of sustainable content such as bio-based or recycled sources can lower a PCF.

PCF Comparison

Sources: https://www.carbon-minds.com/lca-database-for-chemicals-and-plastics/

https://www.silicones.eu/wp-content/uploads/2019/05/SIL_exec-summary_en.pdf

When looking to incorporate sustainable content into your TPE, the raw material cost may be more expensive than traditional materials for three reasons 1) supply chain maturity, 2) high demand, low supply, 3) location of source and supplier. While there are economic challenges amid growing demand, the long-term environmental benefits of sustainable materials far outweigh the cost.

Check out this article to learn more about using sustainable content.

Tooling Costs

In nearly every case, molds needed for LSR fabrication require more precision and tooling expertise than those used to manufacture TPE parts. A 2012 article in Plastics Technology¹ notes silicone rubber molds need tighter tolerances to prevent flash. They also require precise venting and vacuum to release off-gassing during the chemical curing process and must withstand temperatures more than twice that of TPE molds (170°F vs. 320-420°F)

With this level of exactness in engineering and machining, it is important to find a toolmaker with LSR skill and experience. Keep in mind that a limited number of toolmakers specialize in LSR molds—and many are based in Europe. On the other hand, TPEs are most commonly processed using in-line, single-screw injection equipment that has been routinely used in the plastics industry for decades. With that widespread availability also comes a wider selection of mold metals and production techniques.

¹http://www.ptonline.com/articles/getting-into-lsr--part-iv-how-lsr-tooling-is-different

Cycle Time

Thermoplastic elastomers have rapid cooling times and do not require secondary operations or curing agents, which leads to quick turnaround and fabrication. Some products made with LSR require a post cure—heating at high temperatures for a determined period of time—to achieve final dimensions, ensure certain mechanical properties or remove volatiles in applications that have specific regulatory compliance requirements. The post cure process can add several minutes to the production process. However, the low viscosity of LSR makes it possible to realize certain production efficiencies because it can more quickly fill a mold with multiple cavities, depending on part size.

Reprocessability

Since TPEs are a thermoplastic material, they can more easily be reused due to their capability of withstanding repeated melt processes. LSR is a thermoset material. Once a thermoset material is cured with heat it forms a permanent shape that cannot be reheated and reformed.

Performance Comparison

Chemical Resistance

Exposure to chemicals can cause changes in weight, volume and pliability that degrade TPEs and LSR to the point of failure. The type of chemicals your product will encounter and length of exposure is key to determining which material composition will respond the best. It is always sound practice to test your material choices for chemical resistance under actual service conditions to ensure performance.

LSR will generally withstand high levels of exposure to cleaning and disinfecting chemicals, but is susceptible to attacks by concentrated solvents (gasoline, mineral spirits) and acids (sulfuric acid, carbonic acid, citric acid found in car batteries, sodas and juices).¹

Adding filler to LSR will reduce swell caused by chemical exposure, but formulating with too much filler can negatively affect other properties of the material that may be desirable. Fluorosilicones exhibit little swell without the need for fillers, but comes at a price premium.

With a diverse range of formulations on the market today, TPEs exhibit a wide range of resistance to chemicals. Many have been formulated to resist particular chemicals, so you are likely to find a TPE option that will work well in your scenario. Bear in mind, thermoplastic properties of TPEs mean that chemical resistance is most likely to worsen as temperature is raised.

¹http://www.coleparmer.com/Chemical-Resistance

Heat Resistance

As a thermoset, LSR can perform at continuous temperatures in excess of 200°C. This makes LSR an excellent choice in the medical industry as a heat shield for instruments used in cauterization or for any devices that are exposed to repeated high-temperature sterilization. There are medical grade TPEs that can be autoclaved up to 135°C for 15 minutes, but the inherent thermoplasticity of most TPEs make them susceptible to softening under extreme heat.

Compression set performance of LSR and TPEs is comparable at room temperature. (See accompanying Compression Set graph.) LSR responds better under compressive loads as temperatures rise—in dishwasher seals for example.

Barrier Properties

TPEs offer excellent barrier properties against both air and moisture. These properties make TPEs useful in medical applications such as disposable gloves that serve as a guard against biohazards and pathogens without concern for latex allergies. Similarly, impermeable IV-infusion bags can benefit from 2X to 5X extended shelf life with TPEs over conventional materials. In the beverage industry, TPE liners in metal bottle caps effectively protect the taste and freshness of beer, a product that is particularly sensitive to oxygen. Silicone is a breathable material that is beneficial for applications such as wound covering and contact lenses. Incorporating a material like polytetrafluoroethylene will improve the barrier properties of LSR.

Tear Resistance

In Handbook of Polymer Applications in Medicine and Medical Devices,¹ Laurence W. McKeen, PhD, writes, “although fillers may improve properties somewhat, tear and tensile strengths remain relatively low” for LSR. Even a small tear in LSR can lead to catastrophic failure. TPEs can be formulated to achieve high tear strengths as seen in traditional TPE applications such as diapers and exercise bands, where these bands or thin films (as low as 3 mils) are stretched without tearing.

¹http://store.elsevier.com/Handbook-of-Polymer-Applications-in-Medicine-and-Medical-Devices/isbn-9780323221696/

UV Resistance

Consider UV exposure when designing exterior applications, such as window seals and high-voltage line insulators, or items that will be exposed to UV sterilization processes. A transparent part that has yellowed because of UV sterilization may still perform perfectly, but will have an adverse reaction by doctors and patients alike.

LSR is inherently UV resistant and will not degrade when exposed to UV. With the right additives, TPEs can also hold up to UV.

UV attack by sunlight can be prevented by adding UV stabilizers to polymeric materials. These stabilizers usually act by absorbing the UV radiation preferentially, and dissipating the energy as low-level heat.

Source: https://en.wikipedia.org/wiki/UV_degradation

Biocompatibility

LSR has a long-standing track record of use in the medical industry. That's because this material is biologically inert and will not support bacteria growth. Compared to other elastomers, LSR is exceptionally pure. For these reasons alone, LSR is often the natural choice for everything from medical instruments to FDA Class III and USP Class VI implant products, including catheters, gastric feeding tubes, heart valves and stents.

Medical-grade TPEs can rival LSR in biocompatibility performance, depending on their chemistry. And in some cases, the lower production costs of TPEs make them an economical alternative for many single-use products and pharmaceutical-grade delivery tubing.

Check out this case study for a look at how TPEs were able to bring bottom line savings for an infusion pump.

Applications

What’s the best fit for your application? The chart below contains products that benefit from both LSR and TPE materials. Those products that are best served by LSR or TPEs can be found in the left or right columns. The middle column includes items for which both materials can be a good fit depending on specific requirements.

Learn more

Selecting the right material for your application can have multiple nuances, from properties and processing to design and appearance. Check out https://www.avient.com/tpe-knowledge-base to explore the possibilities. Looking for TPEs or LSR tailored for your applications? Contact us at +1.844.4AVIENT (1.844.428.4368) or use our online chat to connect with an expert.