The Challenge

A leading manufacturer of molded auto parts and subassemblies was in a tough spot. Its client – a top global automotive OEM – demanded high-quality parts for its highly engineered performance vehicles.

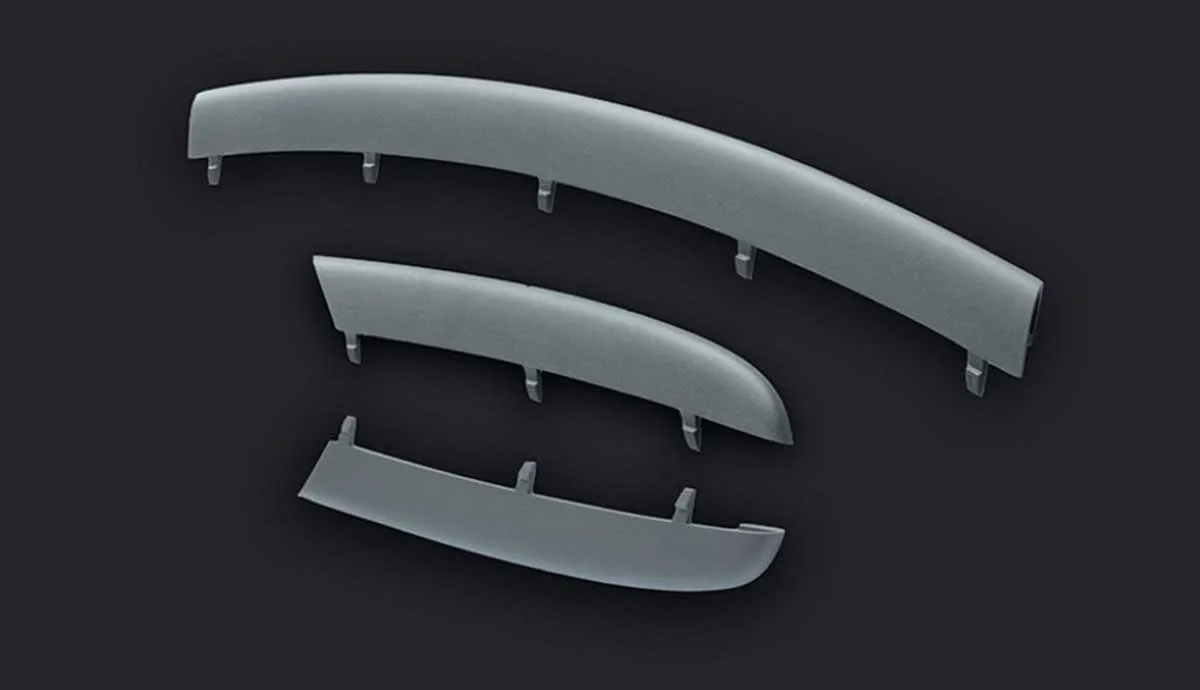

But the manufacturing process for the decorative trim molded from ABS was time consuming, requiring as many as eight steps to complete. After molding, the parts had to be cleaned, primed, painted and clear coated – with three rounds of drying in between.

With multiple locations in Germany, China and the United States, the supplier needed to reduce the number of steps to save time and money – without sacrificing product quality or resistance to UV radiation.

The Solution

The auto parts maker reached out to Avient, which was already was providing it with specialty materials. Working in close cooperation, technical teams from both companies identified a product within the OnColor™ FX Smartbatch portfolio as a potential answer.

The new material, which could be produced in a metallic-effect masterbatch, would allow the supplier to replace the time-consuming painting process. That, in turn, would eliminate emissions of volatile organic compounds (VOCs), which required a costly recovery process under environmental regulations.

The concentrates also would provide UV resistance for color that won’t fade.

The Impact

After making the switch to OnColor FX Smartbatch color and additive concentrates, the supplier achieved a number of significant benefits:

- Cost reduction: Overall improvement in material cost performance versus painted ABS. The total savings varies, depending on color, resin, equipment, and other processing factors.

- Inventory savings: Rather than stocking several pre-colored materials, the molder could purchase and store natural resin that can become whatever color is required when combined with the proper masterbatch.

The switch to masterbatch technology was made without a large capital investment. In addition, equipment costs showed a quick return on investment (ROI) because of the material savings.