What are PFAS?

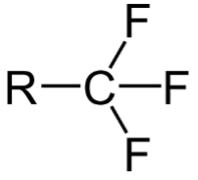

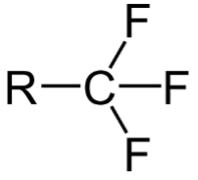

Per- and polyfluoroalkyl substances (PFAS) are defined as fluorinated substances that contain at least one fully fluorinated methyl or methylene carbon atom without any hydrogen, chlorine, bromine, or iodine atom attached to it.

PFAS are widely used in various products to impart properties such as resistance to heat, oil, stains, grease, and water. They are used in a variety of industries such as packaging, healthcare, consumer goods, and industrial materials. Broadly recognized for their chemical inertness, thermal stability, hydrophobicity, low surface energy, and low coefficient of friction (CoF), making them useful in many applications.

Why are there concerns about PFAS?

Legislative and regulatory bodies, as well as some non-governmental organizations (NGOs), have recently intensified their scrutiny of PFAS because studies have shown they may have potential health and safety concerns. This is primarily related to certain PFAS with PBT characteristics (persistent, bioaccumulative, and toxic).

According to some studies, there are also concerns regarding the environmental impact of many PFAS, including perfluorooctanesulfonic acid (PFOS) and perfluorooctanoic acid (PFOA), because they break down very slowly over time in the environment. These concerns include:

- Environmental persistence

- Presence in soil and water

- Buildup (bioaccumulate) in fish and wildlife

The Challenge

PFAS have been commonly used to allow products to meet rigid performance standards while also meeting regulatory compliance. However, with an ever-evolving regulatory landscape and pressures from NGOs and consumers to limit the use of fluorinated substances, companies today are challenged with trying to meet the same product performance characteristics that PFAS provided in the past.

Paths to PFAS Alternatives

There are two basic approaches to consider in developing replacement products:

The first is that companies can develop solutions working with shorter chain length perfluorinated chemicals which have been considered theoretically less persistent and not currently on many restricted lists. These are closer in structure to existing PFAS solutions and, therefore, closer in performance. With this approach, however, questions can remain regarding future regulations and the availability of alternative compounds as they could become restricted. Some states in the U.S. have proposed and/or have passed broad bans on products with PFAS, already leading to issues with short-chain replacements.

The second approach involves eliminating the use of fluorochemicals (the carbon fluorine bond) and working with alternative hydrocarbon chemistries. This approach removes uncertainty regarding the future state of potentially stronger regulations and market pressures. Working with alternative hydrocarbon solutions, which are inherently less robust, requires more customization for a given application, possibly adding complexity to product solutions.

Whatever the approach, there is no one-size-fits-all replacement for the existing PFAS solutions today.

Non-PFAS Development Process and Solutions

Working to provide customers with alternatives, the Avient approach is to follow five key steps:

- Identify target applications

- Select key performance criteria

- Focus on areas that have the greatest chance of success

- Develop internal validation capabilities

- Obtain commercial validation on customer’s equipment

With that in mind, we now have solid and liquid non-PFAS process aid additives for some applications that can eliminate melt fracture and reduce die buildup during processing. We continue to develop other non-PFAS functional additives and solutions to aid in hydrophobicity, moisture repellency, and replacement of CoF PTFE.

Learn more about our solutions here: