What is LFT?

Long fiber reinforced thermoplastic (LFRT) or Long Fiber Thermoplastic (LFT) or Long Fiber Composite is a fiber reinforced injection moldable thermoplastic material. The composite pellet is manufactured through pultruding continuous fiber filaments that are melt permeated with polymer in an impregnation die, creating a product with 20% to 60%, by weight, fiber content that is 12mm in length.

Simply stated, reinforced thermoplastic materials identified as being “long fiber” are those in which the individual reinforcing fibers are of uniform length and are in parallel alignment with each other. In other words, the individual reinforcing fibers are aligned with respect to each other, and are exactly as long (usually 1/2 inch or 12 mm) as the pellet.

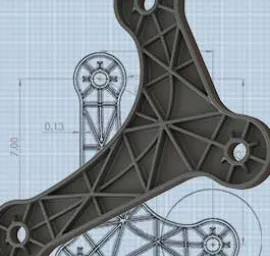

Long fiber reinforced thermoplastic composites are formulated to provide superior physical properties for structural applications. During molding, longer fibers intertwine and align with polymer flow to form an internal skeletal network. This entanglement of longer fibers enables dissipation of stress forces over a wider area creating a tougher part. They are frequently used to replace metal for applications in which light weighting, improved impact strength, elastic modulus, and material strength are required.