How Does Long Fiber Thermoplastics (LFT) Enhance Product Appeal?

As new explorations into innovative materials continue to drive product evolution, Long Fiber Thermoplastics (LFT) are emerging as a compelling alternative to traditional metals across various applications. While LFT has long been recognized for maintaining their mechanical strength after UV exposure, recent advancements have made significant strides in retaining color and gloss levels as well. This development is particularly noteworthy for external applications where visual appeal is crucial, addressing longstanding concerns about aesthetic degradation over time. For R&D professionals and product designers considering material substitutions, LFT now offers a more robust option that can combine structural integrity with long-lasting aesthetics, potentially unlocking new avenues for design freedom, sustainability, and lightweighting in product development.

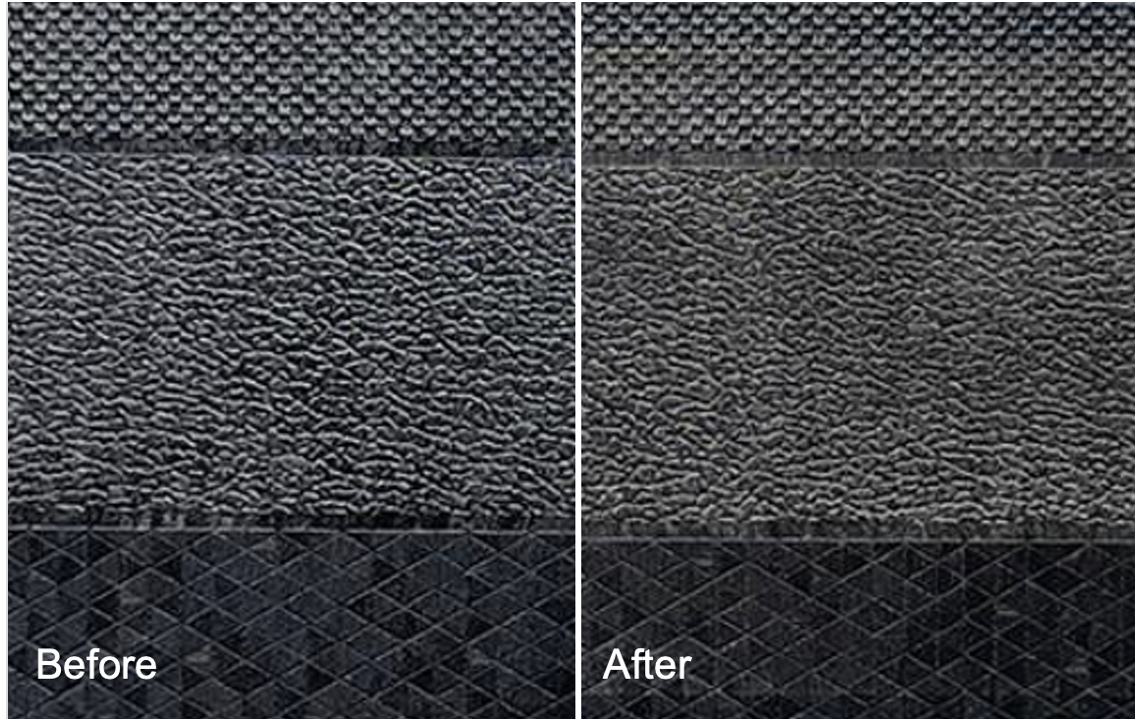

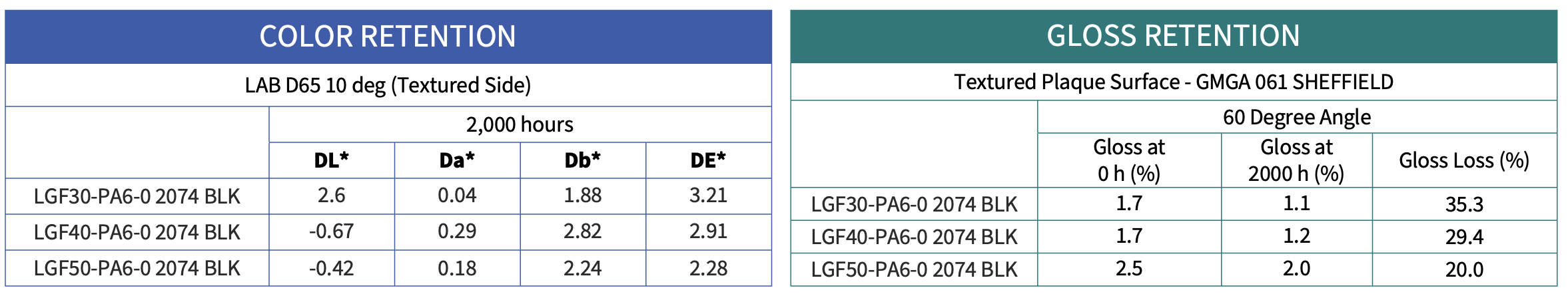

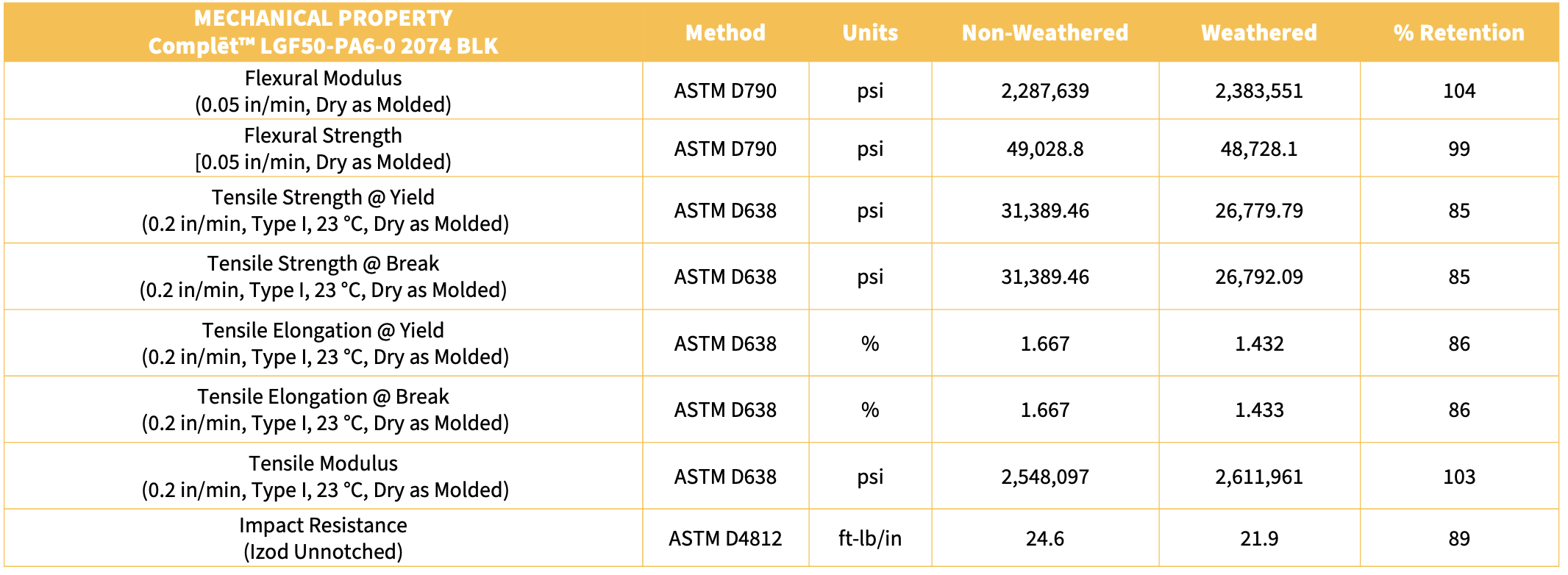

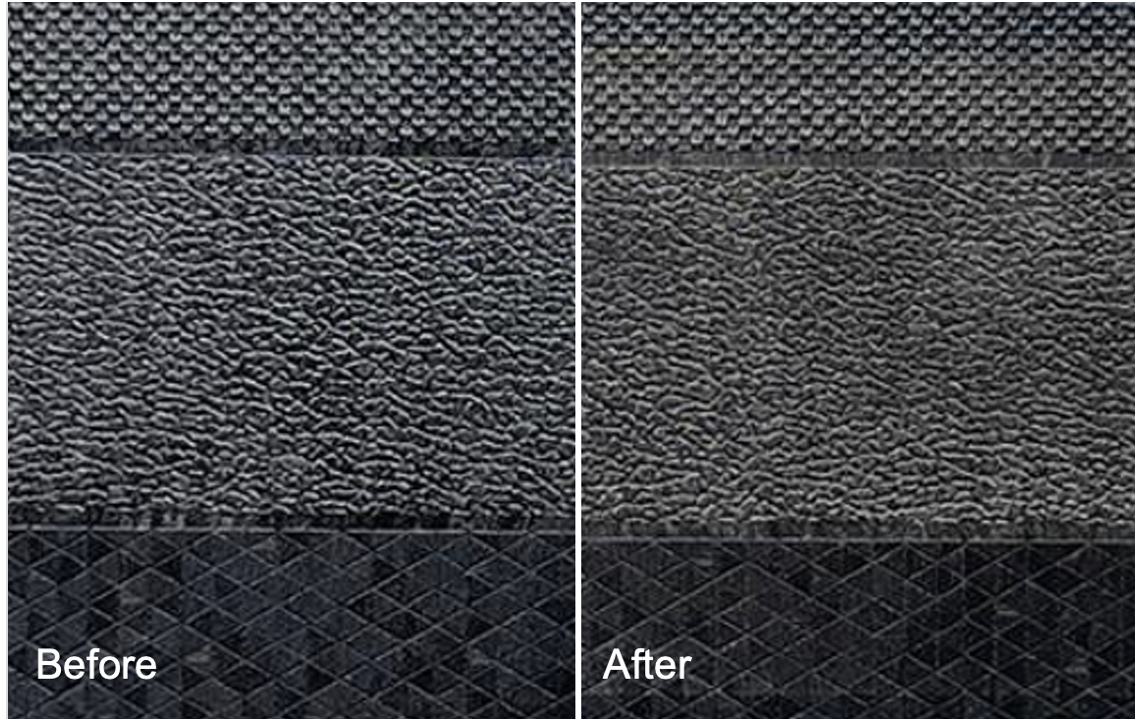

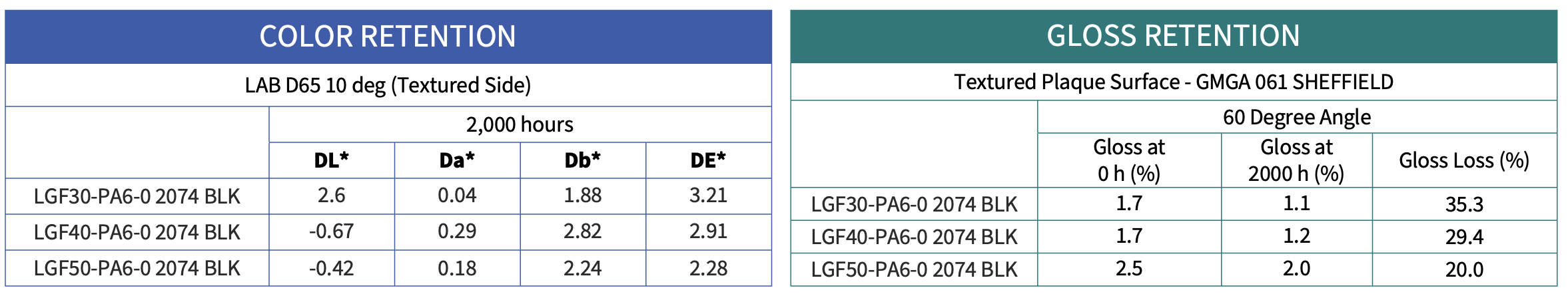

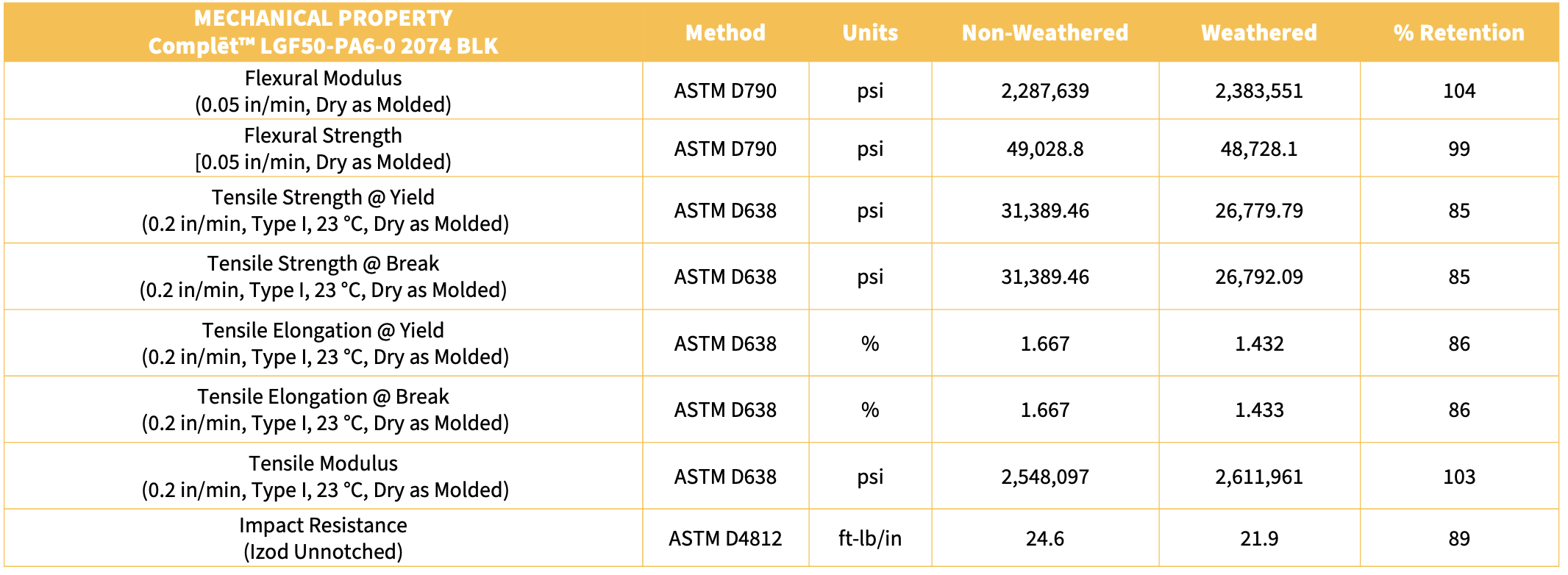

Complēt™ LGF30-PA6 after 2,000-hour weathering study (SAE J2527 – Xenon Arc)

Samples experienced only mild color shift and gloss reduction after exposure.

The Evolution of LFT: Addressing Customer Needs

The enhancement of LFT technologies has been driven by the need to meet customer expectations for products that are both durable and visually appealing. Strengthening in product formulation expands LFT options to improve color and gloss retention after UV exposure, making them useful for demanding exterior applications. This is a significant differentiator in the market, as traditional LFT materials typically compromise on aesthetic qualities to achieve mechanical performance. Now, however, today’s advanced LFTs offer a solution that protects both mechanical and aesthetic performance after UV exposure.

Maintain Color, Gloss, and Strength

Complēt LGF30-PA6 after a 2,000-hour weathering study (SAE J2527 – Xenon Arc) showing maintained mechanical performance and minimal shift in gloss and color.

Key Benefits of Advanced LFT Technologies

- Improved UV Resistance: advanced LFT materials now offer enhanced resistance to UV degradation, maintaining their mechanical strength and visual appeal even after prolonged exposure to sunlight

- Exceptional Color and Gloss Retention: the ability to retain color and gloss levels addresses a critical requirement for external applications where appearance matters, ensuring that products maintain their aesthetic appeal over time

- Proven Mechanical Strength: LFT continues to deliver excellent mechanical performance and strength, a characteristic that has always been a hallmark of these materials

Applications and Opportunities

The advancements in LFT open new possibilities across various industries, particularly in the automotive and consumer goods sectors. By offering materials that can replace metals while maintaining or enhancing aesthetic and structural properties, LFT enables product designers to reimagine their products and capitalize on lightweighting benefits and the processing efficiencies of injection molding. Potential applications include:

- Exterior automotive components

- Structural off-road vehicle applications (roofs, doors, body panels)

- Consumer electronic housings

- Other products requiring both durability and visual appeal

Conclusion

The latest advancements in LFT technologies position these materials as a viable and attractive alternative to traditional options for applications requiring both structural integrity and long-lasting aesthetics. As manufacturers seek innovative solutions that meet evolving customer expectations, LFT stands out as a material that drives product innovation while addressing critical concerns around sustainability, performance, and design flexibility.

For more information on Avient’s LFT technology, please visit Complēt Long Fiber Reinforced Structural Thermoplastics.