Automotive Aftermarket

Long Fiber Thermoplastic Solutions for Aftermarket Parts

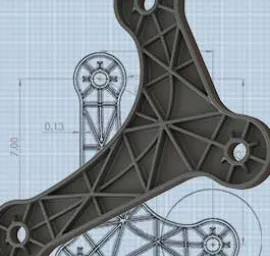

Did you know you can achieve metal-like structural performance with the ease of injection molding? To keep pace with an evolving market, advanced polymer materials can help you meet challenges to reduce part weight, increase resistance to corrosion and rust, and create products with outstanding performance and utility.

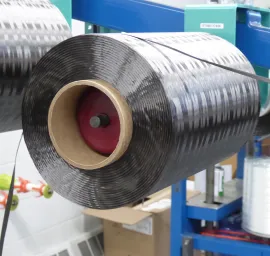

Long fiber reinforced thermoplastics (LFTs) provide alternatives to and benefits over traditional materials used in aftermarket parts, offering designers fresh options with high strength, low density, resistance to moisture absorption, excellent design freedom, and the ability to eliminate secondary processing. Using LFT not only allows for new product innovation, but often drives reductions in system costs and increases in manufacturing efficiencies.

Whether your team is designing running boards, side steps, bed extenders, mounting kits, or a new product to meet changing objectives, our innovative long fiber composites and in-house technical experts can help you break the status quo and rise to the next level of performance and productivity.

LFT Highlights:

- Structural performance on par with metal

- Reduced weight versus metal

- Low moisture absorption versus nylon

- Inherent corrosion resistance

- No secondary processing required

- High design freedom through injection molding

- Recycled content grades available

| Technologies |

|---|

| Complēt™ Long Fiber Reinforced Structural Thermoplastics |

| Complēt™ REC Formulations |

| Complēt™ PKE Formulations |

| Complēt™ MT Long Fiber Composites |

| Complēt™ Moisture Resistant Nylons |